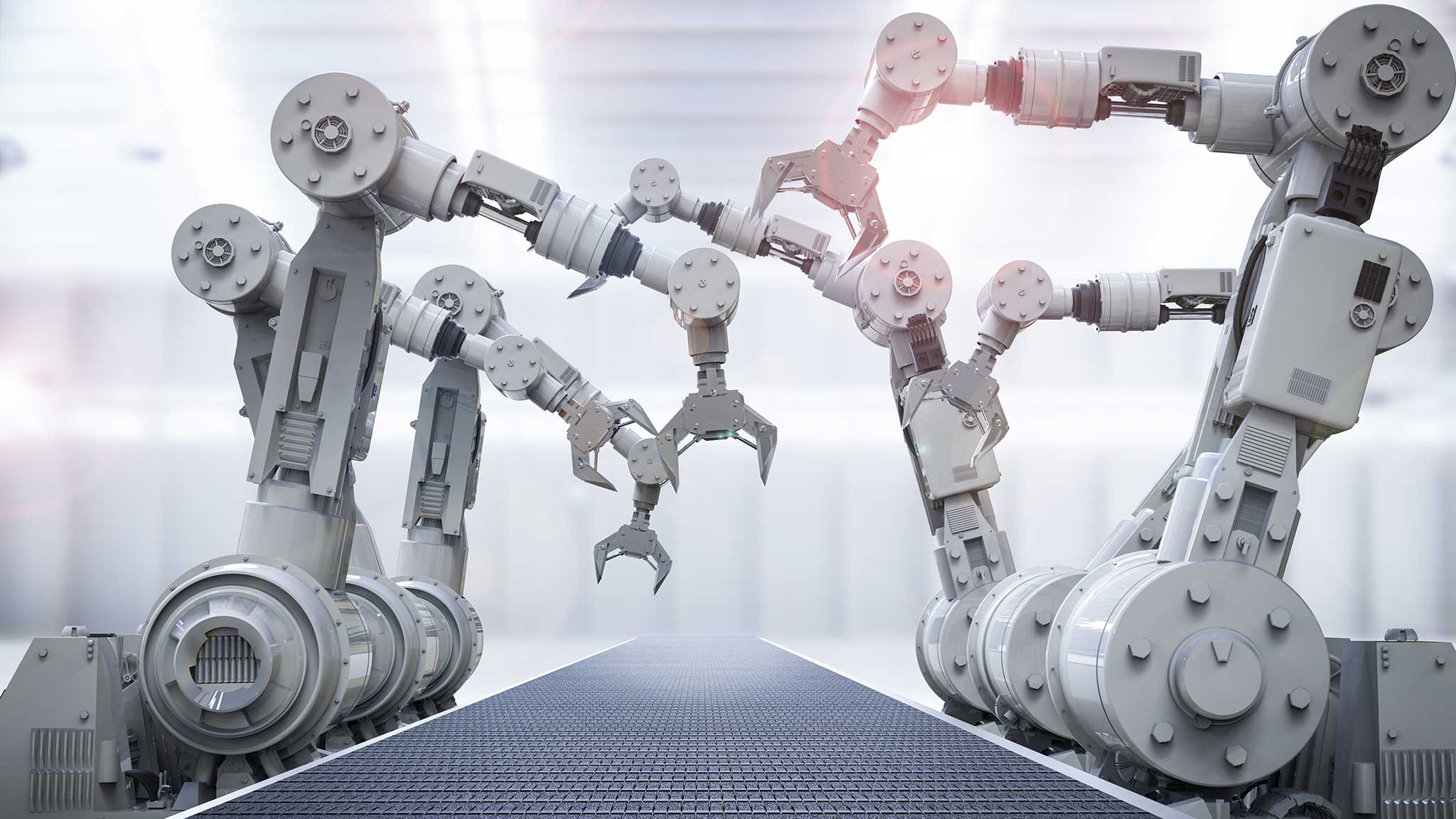

Across the globe, traditional manufacturing industry is in the throes of a digital transformation that is accelerated by exponential growing technologies such as, intelligent robots, autonomous drones, sensors and 3D printing. “Industry 4.0”, the Fourth Industrial Revolution, revolves around networks of manufacturing resources (manufacturing machinery, robots, conveyor and warehousing systems and production facilities) that are autonomous, capable of controlling themselves in response to different situations, self-configuring, knowledge-based, sensor-equipped and spatially dispersed and that also incorporate the relevant planning and management systems. The Fourth Industrial Revolution takes the automation of manufacturing processes to a new level by introducing customized and flexible mass production technologies, where the machines will operate independently, or cooperate with humans in creating a customized production ecosystem that constantly works on evolving itself. It will enable the machines to communicate with each other and with the evolving needs of manufacturers to create a cyber-physical production system (CPPS). Such initiatives will enable the industries to integrate the real world into a virtual one and will facilitate machines to collect real time data, analyze them, and even make decisions.

The rapidly evolving information and communication technologies (ICT) have broken the boundaries separating virtual and the real world. The perception for initiating Industry 4.0 is to create a social network where machines can communicate with each other, called the Internet of Things (IoT) and with people, called the Internet of People (IoP). This networking within an “internet of things, services, data and people” will transform the future of manufacturing. Four main characteristics of Industry 4.0 are:

- Vertical Networking – transforming to smarter/digitized way of production systems, processes, factories, products, logistics, individualized and customized production operations

- Horizontal Integration – creating new generation of global value creation network, integrating business partners and customers across countries and continents

- Thorough Engineering – integrating entire value chain, not just production, but also the service life cycle of product

- Acceleration through exponential technologies – incorporating technologies and inventions to mass market applications, due to reduction in the costs (e.g. Sensor technologies)

We offer the following services:

- Planning and simulation of Smart Factories

- Selection and implementation of Industry 4.0 technologies, methods and tools

- Industry 4.0 for SMEs, e.g. machine data acquisition for SMEs

- Contract research on customized tools

- Analysis of your company’s processes and business model

- Seminars and sensitization of managerial staff and workers to Industry 4.0

- Derivation of potentials

- Definition of demands and selection of systems, including evaluation of cost-effectiveness

- Support in implementing and migrating Industry 4.0 methods and tools

- Documentation of results